Fungal Material Science

Shaping the future with Fungi

Fungi are almost everywhere and have enormous potential as both sustainable final products and components in building materials. Liquid fermentation can provide fast and scalable production of paper-like materials and mono filaments for use in the textile industry. Solid-state fermentation uses the non-fruiting part of the fungus to produce leather like material, insulation or potentially even replace building bricks in houses.

The oCelloScope is used as part of the growth optimization process in fermentations and to test antimicrobial properties of fungal final products.

Image from time-lapse of fungi used in fungal material science

Sustainable textiles

Fungi in fermentations can be used to upcycle byproducts and wastes into flexible fungal materials. At Borås university in Sweden, associated professor Akram Zamani and team have published several papers on turning food waste into fungal mono filament fibers. The fungal biomass is grown on bread waste and fibers are speculated to open new avenues for sustainable biomedical textiles from abundant food waste. Fungal fibers have been shown to exhibit antimicrobial properties.

Left: Fungal mono filament test on bacterial lawn. Assay run on BioSense Solutions mini agar disks. Filament supplied by Akram Zamani, Associate Professor, Dep of Resource Recovery and Building Technology. University of Borås, Sweden

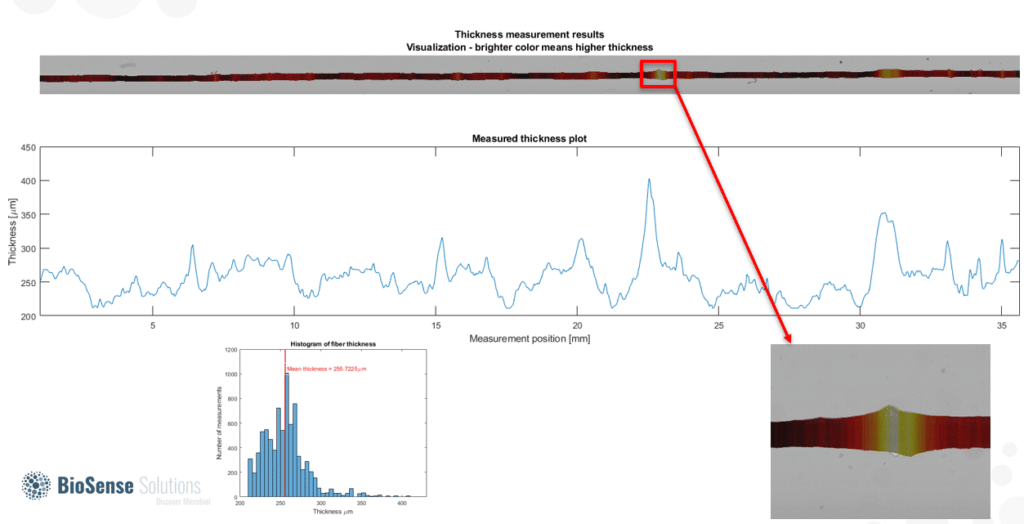

Evaluating uniformity

With new materials comes new needs for quality analysis. With the oCelloScope you can use most assay containers available, such as microtiter plates, microscope slides and flow-cells. In addition, BioSense Solution custom make assay containers/plates for teams

Right: Fungal mono filament scanned with the oCelloScope on microscope slide. Uniformity analysis established.

Filament supplied by Akram Zamani, Associate Professor, Dep of Resource Recovery and Building Technology. University of Borås, Sweden

Ready to get started?

We are ready to help you solve your tough research challenges. Our highly qualified team can help advance your next big discovery.